|

|

|

| Click the picture to enlarge |

|

|

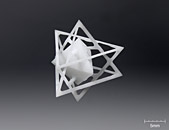

In order to make it more difficult, the shape which cannot be clamped at a plane has been cut. We exercised our ingenuity in cutting with sufficient balance so that the star shape may not collapse and in clamping method.

In particular, since the central block and surrounding wires were all crossed for the clamp method of the 0.5 mm wide star shape, the processing procedure and the clamp method became important.

|

|

|

| Click the picture to enlarge |

|

|

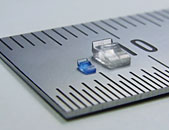

"Further solid object in the solid object."

It is the example of cutting and processing such shape.

We paid special attention to the lattice with 0.5mm per side and the sphericity of the sphere on the center to produce it exercising our ingenuity in the fixed method or the processing method. |

|

|

| Click the picture to enlarge |

|

|

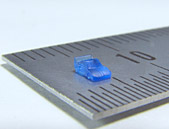

By improving the clamp method of the work, we have achieved the 1/2 size of the miniature car model described below. It is still glossy regardless of its size and finished without breaking the shape of the details. Further minute shape is realized. |

|

|

| Click the picture to enlarge |

|

|

With a R-0.1mm cutter, we have made a full length 2 mm Ferrari.

We put our ingenuity in a process that cuts and grinds both sides, and realized burrless processing.

It is finished with the luster even if the model is small. Moreover, wheel shape of a tire with a diameter of 0.5mm and a detailed shape of the door are reproduced. |

|

|

| Click the picture to enlarge |

|

|

Miniature model of a car-meter parts at a reduction of 1/10

A thin blade of R-0.1mm is used in cutting process to realize the detailed shape.

The transparency of this product is achieved only by processing machines. |

|

|

| Click the picture to enlarge |

|

|

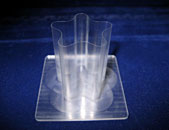

| [Thin Acrylic Slicing Process] |

|

This is a sample case that a fragile acrylic material is processed thinly.

We realized the cutting & grinding process in the dimension of 0.05mm x 38mm (thickness x height) by well-combining the features of processing machine and the condition of cutting & grinding. We have cultivated the longtime know-how and many successful achievements in acryl processing, and this is one of our proud technologies. |

|

|

| Click the picture to enlarge |

|

|

| [Mirrored Acrylic Cutting & Grinding Process] |

|

We realized high transparency in acrylic cutting & grinding process by the method, which is used special tool and high-speed rotary processing machine. We are promoting a development and research on this technology, and accumulating the know-how.

This method is suitable for a (trial) product requiring transparency. |

|

|

| Click the picture to enlarge |

|

|

This is a sample case that an ultra-transparency acrylic spheres without any minute scars is tried to be made. It is finished by our craftsman's handwork after a rough acrylic prototype was produced by a Machining Center. Every surface of a sphere, a cylinder, and a groove on the side is precisely polished and this perfect acrylic sphere shows the professional techniques silently. |

|

|

| Click the picture to enlarge |

|

|

The transparency of this model is achieved by craftsman's handwork that enables to avoid any tiny collapse in the detail, after a rough model was produced from a 50mm-thick acrylic board using special tools and a high-speed rotary processing machine. R-shaped side is realized by delicate cutting using a tiny blade.

It is pursued to realize a precise sharp-edged polyhedron. |

|

|

| Click the picture to enlarge |

|

|

This ceiling light is made with colored acrylic plastic which was finished by Mirrored Grinding Process after processed by Machining Center. A ceiling light could produce impressive atmosphere of a room.

We are pleased to create such a model directly from a design. |

|

|

| Click the picture to enlarge |

|

|

This is a sample case of Plating that an ABC-Resin model produced by the cutting process is used as prototype.

This process (Plating) can be applied to the parts of motorcycles, cars and household electric appliances for the decorative, functional and anti-rust purpose. A type and thickness of Plating is varied and to be decided through a discussion with a client considering the requested model's shape, size and nature. |

|