|

|

|

For productivity improvement and a secure guaranteed quality, we take care of all the stages from idea to design and production, and offer the best Jig to customers for their complete satisfaction.

|

|

|

|

| ■ |

Realize Your Idea and Image |

|

We will hear your requests from planning stage and implement the design and manufacture. Even if specification or form is not determined, you can consult about the use or the purpose with us and we will propose adequate jigs. |

| ■ |

Pursue the effectiveness of work and light-weighting |

|

It is also an important issue to reduce worker’s burden especially in repeated tasks.

We solve the problems regarding functionality and effectiveness of work, and provide a light-weighting scheme to customers with applying our technology of resin rapid prototyping system. |

| ■ |

Pursuit of Cost Performance

|

|

After full consideration of the demanded function of Jig, we make every effort for customers to minimize cost by using conventional parts actively.

|

|

|

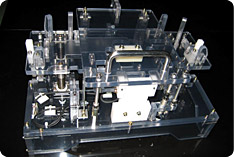

Antielectricity vinyl chloride plate, Aluminum, POM |

|

|

|

|

|

| Case screw tightening jig |

4.65kg |

| Base screw tightening jig |

2.80kg |

|

|

|

|

|

|

| Case screw tightening jig |

X420 Y310 Z160 |

| Base screw tightening jig |

X350 Y220 Z60 |

|

|

|

|

|

|

It is a jig to perform screw fastening for fixing a base to a case.

By attaching the guide of screw fastening to jig, falling of a screw and entering at a slant in a case will be prevented. The sensor is attached for preventing malfunction in case that the work has not been done normally, including that a case does not fit in home position. |

|

|

|

|

|

About 8 days |

|

|

|

|

|

Antielectricity vinyl chloride plate, Aluminum, POM |

|

|

|

|

|

7kg |

|

|

|

|

|

X500 Y400 Z200 |

|

|

|

|

|

It is a jig for attaching FPC (flexible printed circuit board) to the connector part of a case.

Assembling at a small space which is difficult manually can be performed by easy operation.

Since the arm returns to the original position after the assembling is completed, secure and efficient work can be done. |

|

|

|

|

|

About 1 month |

|

|

|

|

|

MC nylon, Aluminum, SUS |

|

|

|

|

|

15kg |

|

|

|

|

|

X700 Y700 Z400 |

|

|

|

|

|

Since even varied products can be set without changing the standard, it is not necessary to produce the test jig for every variation. |

|

|

|

|

|

About 1 month |

|

|

|

|

|

Antielectricity vinyl chloride plate, SLS (Selective Laser Sintering) article |

|

|

|

|

|

3.32kg |

|

|

|

|

|

X440 Y250 Z185 |

|

|

|

|

|

Foreign substances in the W/P dial are sucked in by air blow before G/F are mounted to remove dust.

*G/F...Glass front W/P...Window plate |

|

|

|

|

|

10 days |

|

|

|

|